As you can imagine, keeping the farm running requires a pretty comprehensive array of machinery, equipment, vehicles and tools: we’ve got tractors, diggers, hen houses, buggies, egg belts, feed silos, delivery vans, feeders, fencing… the list goes on (and there’s an even longer list running alongside it to make sure everything is maintained and in good working order).

But, if there’s one single piece of machinery that, if it were to stop working, could bring our entire operation to a grinding halt it is probably the Grader. It is central to the sorting, stamping and sizing of every single egg that leaves this farm - no Grader, no eggs are going out!

Most eggs in the UK and Europe are graded and packed in large computer-controlled ‘packing stations’ that can automate the sizing and quality control of thousands of dozens of eggs an hour. That’s not the Rookery way, however!

Whether it’s how we go about farming or how we go about grading, we favour a more ‘hands-on’ approach that, while definitely more labour-intensive, we believe, makes a big difference to the final product. (You can read more about how we farm and grade our eggs here)

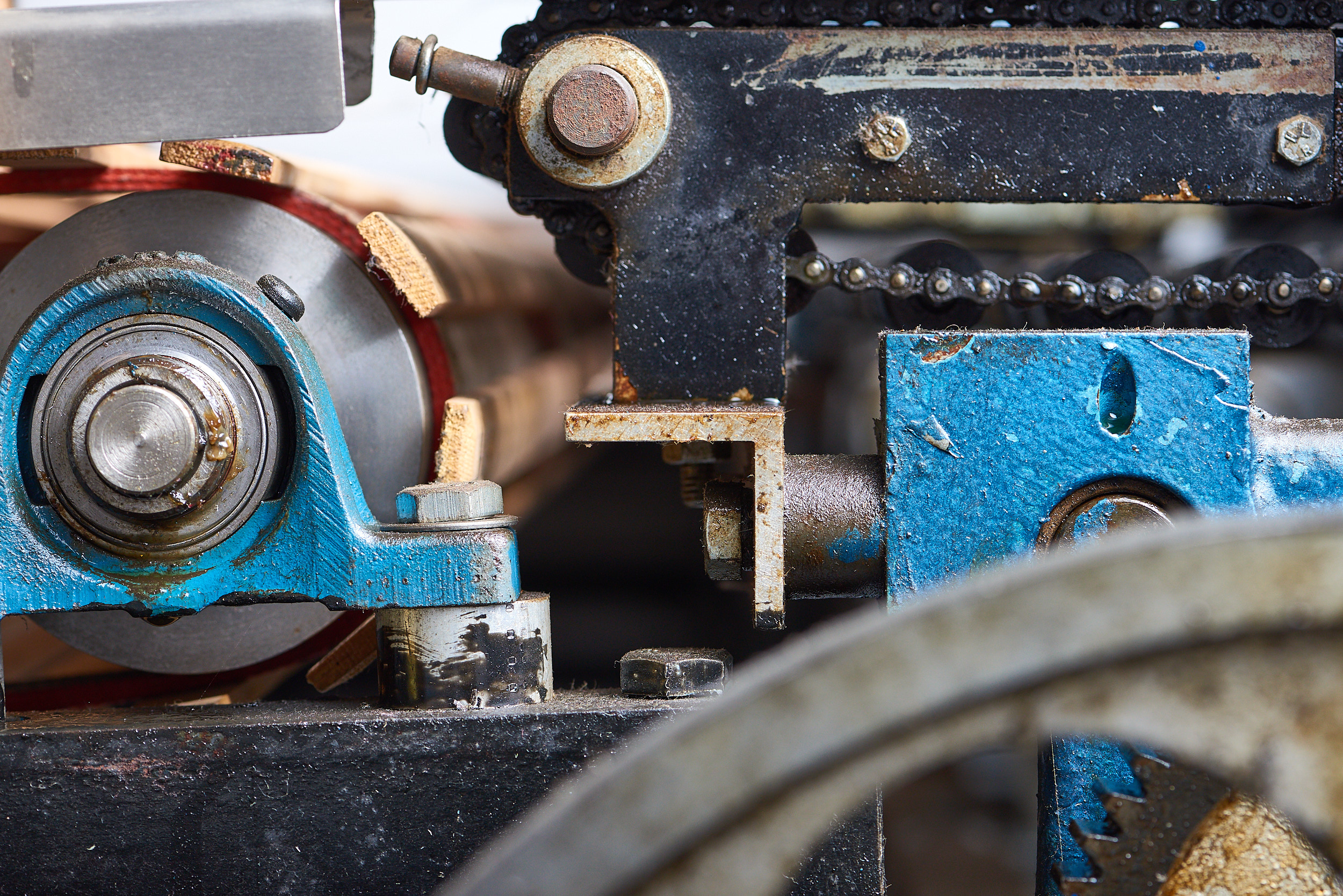

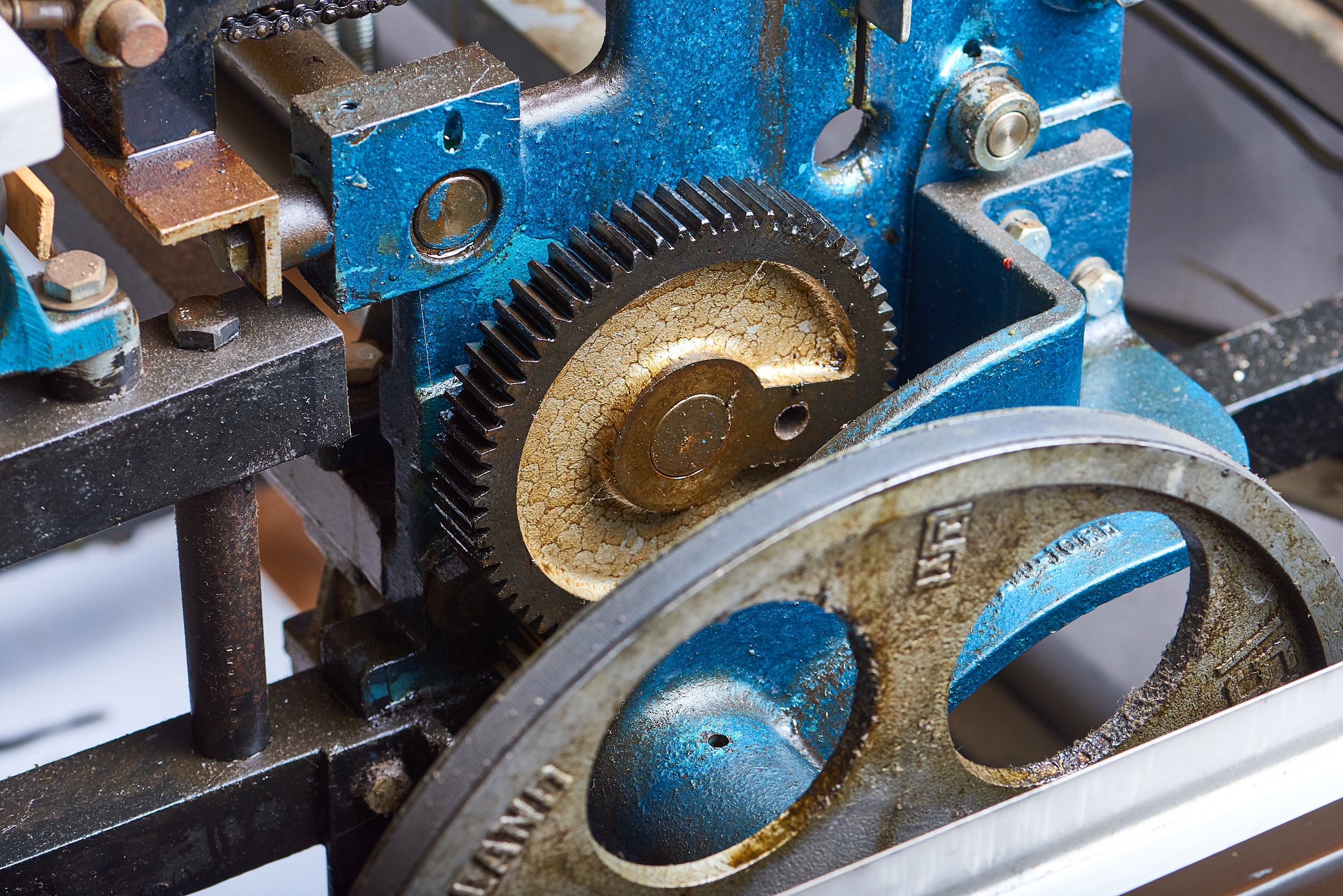

Until now, all grading duties have been taken care of by our trusty Ben Nevis Mechanical Grader, which we bought refurbished about 25 years ago. That machine is probably 40 years old at this point and, with hundreds of thousands of eggs over its belts, it has more than earned its retirement. The question then was what to replace it with?

Well, if it ain’t broke why fix it? And if it is broke we want to be able to fix it… ourselves rather than calling and waiting for a technician, which is one of the reasons we prefer more ‘old school’ mechanical graders to their computerised counterparts.

While the original Ben Nevis company no longer exists, a small one-man operation based in Wigan (?), specialises in taking old Ben Nevis machines and customising them for the demands of today. So that’s who we worked with to spec and build a machine customised for Rookery Farm in this millennium.

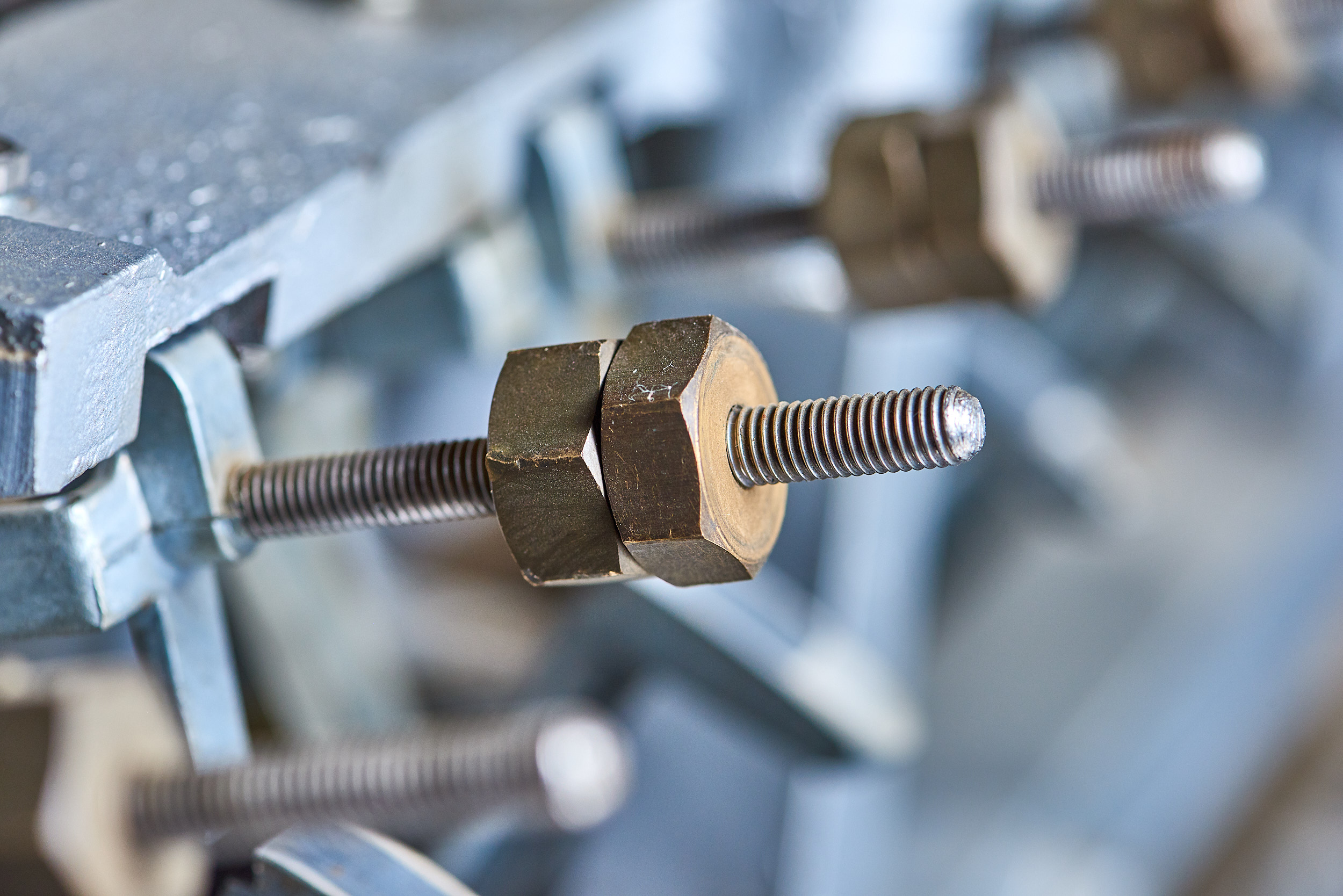

While its’ external skin is shiny new stainless steel, the mechanical guts of our new grader are not dissimilar to its’ predecessor. So we know exactly how to go about servicing and troubleshooting it, while benefitting from a number of significant upgrades. For example, we now have the capacity to grade 40-45% more eggs per hour should we need to, thanks to an increased number of ‘lanes’. The candling station has been re-designed to make spotting imperfections in the shells easier and more efficient. Meanwhile, the stainless steel exterior is easier to clean and maintain which, again, leads to greater efficiency.

The real benefit to us however is flexibility. While the new grader is certainly more efficient, and increased efficiency would usually mean a reduction in costs, we believe people are still the best way to ensure we deliver a consistently high quality product. Everything is still ultimately done by hand - so increasing capacity means increasing the number of people needed as the grader is still loaded manually, candling and quality control is still all manual and every carton of eggs is still packed by hand. So it’s a pretty significant investment in both machinery and labour but people seem to love our eggs and this way we can continue to meet demand without compromising our approach, and to us that’s worth it.